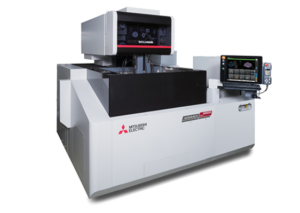

EA8S

The Mitsubishi EA-S with the new M700 controller with 15” touch screen and FP80S energy-saving power supply, reducing electrical consumption.

These machines are the compact Highly-Rigid Machines and fixed Table Traveling Column Construction with all-new Power Master GF2 Adaptive Control reduces graphite electrode wear.

The Intelligent Digital Power Master (IDPM) is the key to the special performance attributes of the EA-S. Minimal graphite electrode wear with high erosion rates and high performance in the machining of carbide.

The addition of the new SS Jump 5 optimizes jump up acceleration control to stabilize high-speed No-Flush burning

With new features that will advance EDM machining, the EA-S is truly a revolution in Sinker EDM technology.

Product sales enquiry form

Customer Enquiry Form

| Standard Machine Specifications - Automatic Elevation Tank | ||

|---|---|---|

| Machine travel [ X x Y x Z ] | - | 300 x 250 x 250 mm |

| Max. work-piece dimensions [ W x D x H ] | - | 770 x 490 x 200 mm |

| Max. work-piece weight | - | 550 Kg |

| Axis movement | - | Fixed table, Column Movement |

| Dist. b/w table & electrode mount face | - | 150 to 400 mm |

| Max. electrode weight | - | 25 Kg |

| Unit weight | - | 2000 Kg |

| Initial Dielectric fluid amount | - | 270 Ltr |

| Dielectric fluid chiller unit | - | In-build unit cooler |

| Method of Working tank door | - | Automatic elevation tank |

| Max. machining peak current | - | 80 A (120 option) |

| Power requirement | - | 6.5 KVA (9.5 option for 120 supply) |

| User memory capacity | - | 1 GB |

| Min. drive unit | - | 0.1 µm |

| C - Axis and Automatic tool changer | - | Available as option |

| Features related to Industry 4.0 | - | Remote 360 |

| Standard Machine Specification - Manual Hinge Door | ||

| Machine travel [ X x Y x Z ] | - | 300 x 250 x 250 mm |

| Max. work-piece dimension [ W x D x H ] | - | 770 x 490 x 200 mm |

| Max. work-piece weight | - | 550 Kg |

| Axis movement | - | Fixed table, Column Movement |

| Dist. b/w table & electrode mount face | - | 150 to 400 mm |

| Max. electrode weight | - | 25 Kg |

| Unit weight | - | 2000 Kg |

| Initial Dielectric fluid amount | - | 260 Ltr |

| Dielectric fluid chiller unit | - | In-build unit coller |

| Method of Working tank door | - | Hinge type door |

| Max. machining peak current | - | 80 A (120 option) |

| Power requirement | - | 6.5 kVA (9.5 option for 120 supply) |

| User memory capacity | - | 1 GB |

| Min. drive unit | - | 0.1 µm |

| Automatic tool changer | - | Available as option |

| Features related to Industry 4.0 | - | Remote 360 |