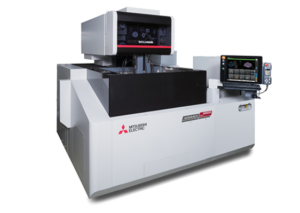

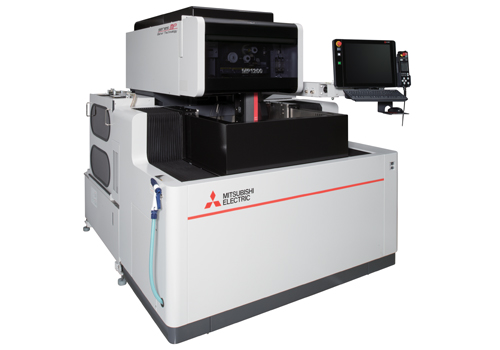

MP1200

MP1200 Wire EDM is Outstanding accuracy for the most critical application. This machine is designed for Ultra precision components with higher surface quality and lower power costs.

This machine reacts with greater speed and precision achieves better surface quality faster. The voltage is built up faster and with greater precision thanks to reduced capacitance loss. The standard SDFS circuit delivers the best finish in less machining time.

The machine exemplifies Mitsubishi EDM’s continued dedication to high precision and innovative technology with the highly reliable non-contact Cylindrical Drive System on the X, Y, U & V axis drives.

“Thermal Buster” which is a thermal stability system that circulates chilled dielectric fluid to key

areas throughout the machine structure.

The exceptionally heavy-duty machine bed, only the best, top-flight linear guides and precision assembly ensure the best wire-cutting results in the long term.

With advancements in machine construction and power supply technology, the MP1200 is sure to revolutionize EDM machining and increase your precision in machining.

Product sales enquiry form

Customer Enquiry Form

| Standard Machine Specifications | ||

|---|---|---|

| Machine travel [ X x Y x Z ] (mm) | - | 400 x 300 x 220 |

| Machine travel [ U x V ] (mm) | - | ±60 x ±60 |

| Max. work-piece dimensions [ W x D x H ] (mm) | - | 810 x 700 x 215 |

| Max. work-piece weight (kg) | - | 500 |

| Motor system [ axis ] (-) | - | XY-UV axis LSM-OPT drive |

| Wire diameter range (Ø mm) | - | 0.10 to 0.3 (0.05, 0.07 option) |

| Max. taper angle (Degree) | - | 15⁰ @ 200mm, 30⁰ @ 87mm |

| Unit weight (Kg) | - | 3100 |

| Dielectric fluid tank capacity (Ltr) | - | 550 |

| Dielectric fluid chiller unit | - | In-build unit cooler |

| Max. output current (A) | - | 50.0 |

| Power requirement (kVA) | - | 13.5 |

| User memory capacity (GB) | - | 1 |

| On board CAD/CAM | - | Available, 2D CAM MAGIC |

| Min. axis resolution (µm) | - | 0.05 |

| Wire threading method | - | Automatic Wire Threading - Intelligent AT |

| Features related to Industry 4.0 | - | Remote 360 |