Laser Processing Solutions

We introduced our first commercial laser cutting machine in 1977.

Delivers unprecedented performance, creating the future of laser processing.

We design and manufacture every critical component that goes into our laser system from the cutting machine to resonator and control unit. Our vast line-up of 2D and 3D laser processing machines offer the ultimate in speed, accuracy and flexibility.

We’ve been improving the technology—making it do more with fewer resources, making it easier for operators to use, and much more—ever since.

-

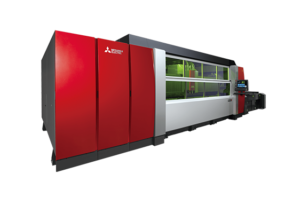

Fiber Laser

Fiber laser takes Mitsubishi Electric laser processing machines to an even higher level. The Mitsubishi Electric fiber laser series is equipped with High-speed Control for Lasers (MHC-L), our original control method, which eliminates the need for axes to stop.

Read More -

Five-Axis CO2 Lasers

3D laser processing machines open the door to new laser cutting/welding applications. From prototypes to production runs, Mitsubishi Electric 3D laser processing machines offer the ultimate in accuracy, speed and efficiency.

Read More -

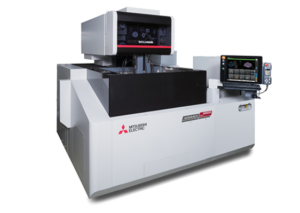

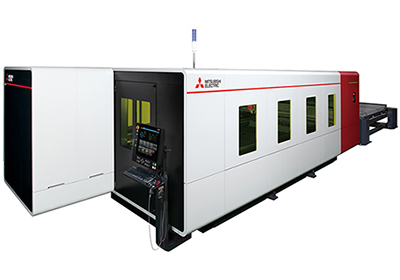

2D CO2 Lasers

We offer several cost-effective 2D CO2 laser machines. Our laser machines can help you reduce gas costs, improve efficiencies, step up your cycle times and increase overall profit—thanks to superior design and the best resonators on the market.

Read More -

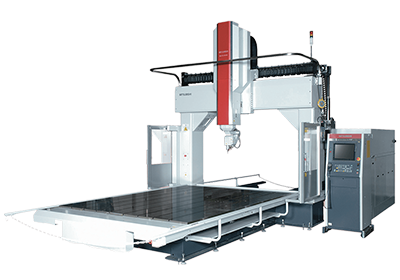

Nissan Tanaka Gantry Laser

As a pioneer in gantry type laser TANAKA introduced into market the world first "Oscillator integrated type laser cutting machine" in 1989.

Read More -

Laser Consumables

To keep your machinery pure, be sure to feed it the right OEM-specified replacement parts, Lens, Nozzle, filters, and other consumables.

Read More