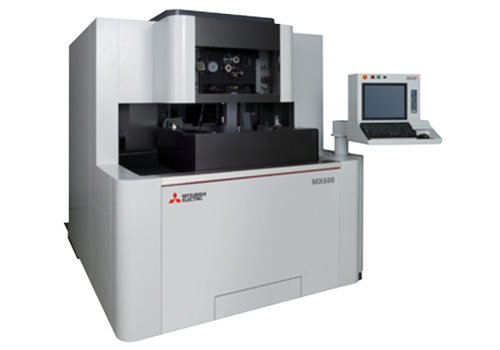

MX600

MX-series Wire EDM machine is designed with Oil base machining that realizes Ultra-high precision machining even during long term continuous operation.

With a single unit, you can achieve a variety of high precision die machining for small precision electronic components and drive components for medium-sized automobiles.

MX machines adopted with next-generation drive system and high rigidity casting for highly accurate machining in long processing by standard on the three-sided lifting working tank and automatic operation.

With advancements in machine construction and power supply technology, this MX-series Flagship model is sure to revolutionize Oil base Wire EDM machining and increase your precision in machining.

Send Enquiry

Product Brochure

Promotion Video

Intelligent AT

Intelligent Submerged AT

Fine Wire Machining

Power Master

B-axis

Collision protection

On board CAM Feature

Product sales enquiry form

Customer Enquiry Form

Specification

| Standard Machine Specifications | ||

|---|---|---|

| Machine travel [ X x Y x Z ] (mm) | - | 300 x 200 x 180 |

| Machine travel [ U x V ] (mm) | - | ±35 x ±35 |

| Max. work-piece dimensions [ W x D x H ] (mm) | - | 620 x 610 x 100 |

| Max. work-piece weight (kg) | - | 300 |

| Motor system [ axis ] (-) | - | XY & UV axis LSM-OPT drive |

| Wire diameter range (Ø mm) | - | 0.04 to 0.2 (0.03 option) |

| Max. taper angle (Degree) | - | 15⁰ @ 100mm |

| Unit weight (Kg) | - | 3400 |

| Dielectric fluid tank capacity (Ltr) | - | 300 (oil) |

| Dielectric fluid chiller unit | - | In-build unit cooler |

| Max. output current (A) | - | 50.0 |

| Power requirement (kVA) | - | 13.5 |

| User memory capacity (GB) | - | 1 |

| On board CAD/CAM | - | Available, 2D CAM MAGIC |

| Min. axis resolution (µm) | - | 0.05 |

| Wire threading method | - | 0.05 Automatic Wire Threading - Intelligent AT |

| Features related to Industry 4.0 | - | Remote 360 |