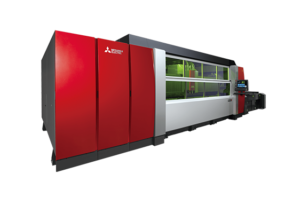

ML2512HV2-R

True standard machine exceeding its own limits

High productivity

High-speed height control, latest trajectory control and piercing technology delivers the hybrid’s maximum performance on thin to thick plates. Results in drastic reduction in processing times.

Operability

New control unit improves operability and automated adjustment enables comfortable, stress-free operation, from setup to processing.

Additionally, the total time from setup to product completion has been shortened, enabling quick turnaround.

Diverse processing

Z-axis stroke enables processing of boxed objects and tubes. By further expanding the processing conditions database, a wider variety of materials can be handled, thus increasing the potential of laser processing.

Specification

| Laser Processing Machines Specifiactions | ||

|---|---|---|

| Model | - | ML2512HV2-R |

| Drive System | - | Hybrid type (X axis: Table movement, Y & Z axis : Beam movement) |

| Control System | - | X-Y-Z simultaneous 3 axis ( Z axis height control is also possible) |

| Workpiece dimensions (mm) | - | 2440 x 1220 |

| Stroke X-axis (mm) | - | 2500 |

| Stroke Y-axis (mm) | - | 1250 |

| Stroke Z-axis (mm) | - | 300 |

| Rapid feed rate (combined) XY-axis (m/min) | - | Max. 70 (combined) |

| Positioning accuracy XY-axis (mm) | - | 0.01/500 |

| Positioning accuracy Z-axis (mm) | - | 0.01/100 |

| Repeatability XY-axis (mm) | - | ±0.005 |

| Table Pass height (mm) | - | 850 |

| Footprint (reference value in mm) | - | 8800 x 3760 |

| Machine weight (kg) (excluding oscillator) | - | 7600 |

| Pallet Changer weight (kg) | - | N/A |

| Applicable oscillator | - | ML20XF, ML32XP, ML45CF-R |