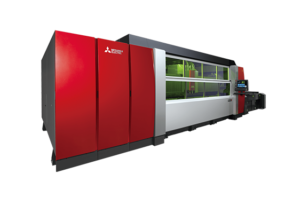

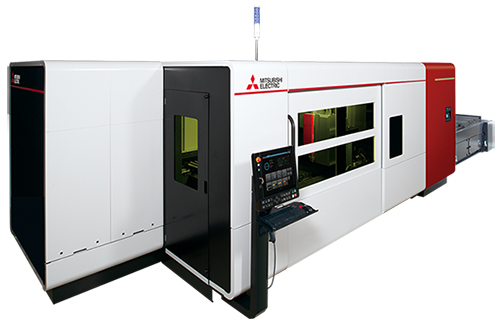

ML3015GX-Advanced

Introducing the highly reliable AI-powered “Non-stop Processing System” All-Mitsubishi Fiber Laser

Mitsubishi Fiber Laser Oscillator

Achieves both high reliability and high productivity with our new fiber laser oscillator built-in. Minimizes the risk of machine breakdowns.

AGR-eco

Our proprietary gas flow control reduces nitrogen gas consumption by up to 90%. The processing speed and cutting surface quality have been improved for everything from thin to thick plates, providing unprecedented added value.

AI Assistance

The processing state is determined from the sounds and light during processing with AI, using our AI technology “Maisart®”. In pursuit of a “non-stop processing system”, with the world’s first e-laser processing system built-in and functionality that automatically adjusts the laser processing conditions with AI.

Product sales enquiry form

Customer Enquiry Form

| Laser Processing Machines Specifiactions | ||

|---|---|---|

| Model | - | ML3015GX - Advanced |

| Drive System | - | Flying Optics ( 3-axis beam travel) |

| Control System | - | X-Y-Z simultaneous 3 axis ( Z axis height control is also possible) |

| Workpiece dimensions (mm) | - | 3050 x 1525 |

| Stroke X-axis (mm) | - | 3100 |

| Stroke Y-axis (mm) | - | 1565 |

| Stroke Z-axis (mm) | - | 120 |

| Rapid feed rate (combined) XY-axis (m/min) | - | Max. 170 (combined) |

| Positioning accuracy XY-axis (mm) | - | 0.05/500 |

| Positioning accuracy Z-axis (mm) | - | 0.1/100 |

| Repeatability XY-axis (mm) | - | ±0.01 |

| Table Pass height (mm) | - | 890 |

| Footprint (reference value in mm) | - | 13000 x 5200 |

| Machine weight (kg) (excluding oscillator) | - | 7000 |

| Pallet Changer weight (kg) | - | 2400 |

| Applicable oscillator | - | MF40/60/80/100 |