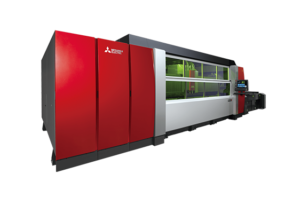

ML3015eX-PLUS

High standard machine that achieves extraordinary productivity and top-quality results

High Performance

The faster processing speed and optimized control system of the eX PLUS series reduces thin-plate processing time by approximately 42%. The cutting-edge piercing technology allows for about a 48% reduction in processing time of mid-thick and thick mild steel plates.(in-house comparison)

Simple Operation

2 Action Cutting allows for the entire process, from job setup to parts cutting, to be completed in two simple actions. Delivers easy operation and stable performance. CAD/CAM computer, connected via network, is a great aid for operators on the shop floor.

Ecology

When not processing, the system switches to ECO mode and the resonator stops idling. Minimizes energy consumption, reducing running costs by up to 99% during standby. Quickly resumes normal operation. Mitsubishi Electric’s original resonator reduces CO2 emissions by approximately 30% compared to standard high-speed, axial-flow resonators.(in-house comparison)

| Laser Processing Machines Specifiactions | ||

|---|---|---|

| Model | - | ML3015eX-PLUS |

| Drive System | - | Flying optics (3-axis beam travel) |

| Control System | - | X-Y-Z simultaneous 3 axis ( Z axis height control is also possible) |

| Workpiece dimensions (mm) | - | 3050 x 1525 |

| Stroke X-axis (mm) | - | 3100 |

| Stroke Y-axis (mm) | - | 1565 |

| Stroke Z-axis (mm) | - | 150 |

| Rapid feed rate (combined) XY-axis (m/min) | - | Max. 140 (combined) |

| Positioning accuracy XY-axis (mm) | - | 0.01/500 |

| Positioning accuracy Z-axis (mm) | - | 0.01/100 |

| Repeatability XY-axis (mm) | - | ±0.01 |

| Table Pass height (mm) | - | 880 |

| Footprint (reference value in mm) | - | 13190 x 5150 |

| Machine weight (kg) (excluding oscillator) | - | 8500 |

| Pallet Changer weight (kg) | - | 2100 |

| Applicable oscillator | - | ML45CF-R/60XF |