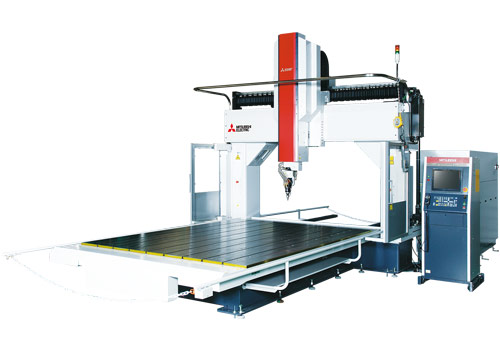

ML1515VZ20

Towards versatility and new possibilities… Devoting limitless passion to 3D laser processing

Wide range of applications

The VZ20 series expands the range of laser applications in welding and thick-plate cutting. The maximum thickness of stainless steel that can be cut using nitrogen assist gas has increased 2.5 times compared to our previous model.

Offset processing head

The Offset Head is slimmer than ever, realizing superior work piece accessibility and lower chance of collision with the work piece and jig. VZ20 is the perfect choice for the processing of deep drawn parts.

Operability

Simplified teaching box dramatically reduces keystrokes during programming and allows for quicker job setup including program correction.

Send Enquiry

Product Brochure

Promotion Video

Function & Operational video

Product sales enquiry form

Customer Enquiry Form

Specification

| Specification | ||

|---|---|---|

| Model | - | ML1515VZ20 |

| Operation Type | - | Hybrid |

| Processing Head Structure | - | offset |

| Control System | - | X-Y-Z-C-A 5-axis, Simultaneous Control |

| Workpiece dimensions (mm) | - | 920x920x550 |

| Max. 2D work piece size (C-axis 90° fixed) | - | 1520x1320 |

| Stroke X,Y,Z-axis(mm) | - | 1520x1520x850 |

| Stroke W,U-axis (°) | - | - |

| Stroke C,A-axis (°) | - | C: ±360, A: ±90 (±135° optional) |

| Rapid feed rate X,Y,Z-axis(m/min) | - | X, Y: 45 / Z: 35 |

| Rapid feed rate W,U-axis (°/s) | - | - |

| Rapid feed rate C,A-axis (°/s) | - | 360 |

| Max. Cutting Speed X,Y,Z-axis(m/min) | - | 35 |

| Max. Cutting Speed W,U-axis (°/s) | - | 360 |

| Repeatability (mm) | - | ±0.015 |

| Table weight (Kg) | - | 700 |

| Table Pass height (mm) | - | 650 |

| Footprint (reference value in mm) | - | 6300x4250 |

| Machine weight (kg) (excluding oscillator) | - | Approx. 6000 |

| Applicable oscillator | - | ML20XF, ML40CF-R |