EDM Processing Solutions

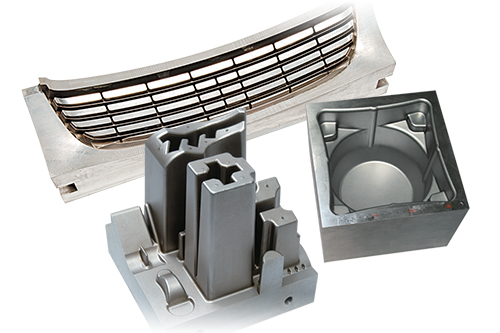

Where detailed, efficient metal removal is difficult or impossible to do accurately by conventional means, electrical discharge machining (EDM) is the practical choice. It’s predictable, accurate, and repeatable.

But when it comes to delivering quality at scale, cutting timelines without cutting corners, and making quick work of high-tolerance jobs, you’ll need an advantage over typical EDM solutions. And that’s where we come in.

If you’re machining small, tight-tolerance items where accuracy is key—like in Automobile, Aerospace, Energy and Medical segments—you need a reliable, cost- and resource-efficient solution that’s easy to use and easy to trust

-

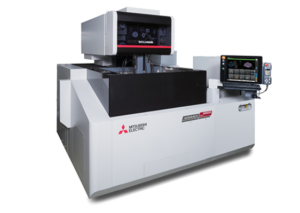

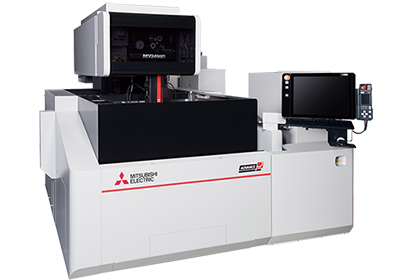

Wire EDM

Electrifying innovation - As a leader in the wire EDM market, we never stop looking for ways to innovate. A perfect example: the new cylindrical-drive technology of our MV series wire EDM machines.

Read More -

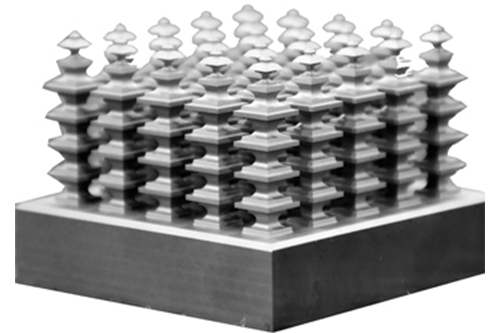

Sinker EDM

When it comes to razor-sharp accuracy, nothing beats our sinker EDM machines. Advanced controls, EDM automation capabilities and a superior power supply make these sinker EDM machines the ideal choice for tight-tolerance applications.

Read More -

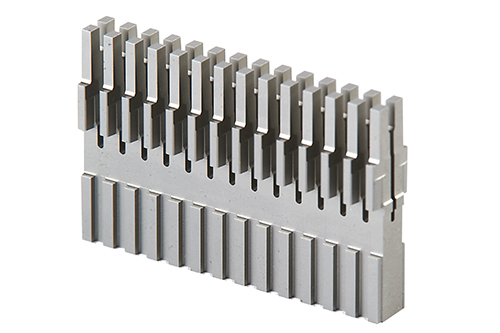

EDM Consumables

To keep your machinery pure, be sure to feed it the right OEM-specified replacement parts, wires, filters, and other consumables.

Read More