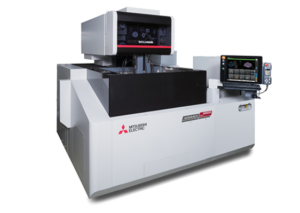

SV12P

SV-P series is the Next-generation Sinker EDM machine incorporating the Maisart (Mitsubishi Electric’s AI creates the State of the ART in technology) and M800 controller unit (D-CUBES) to pursue both high performance and high productivity.

Automatic depth recognition and stable servo control using “Maisart” make uniform surface finish. The all new M800 D-CUBES controller with 19 inch touch screen is like a smartphone and new thin operation box is a standard equipment for easy operating and programming.

The Mitsubishi SV-P series with “Thermal Buster” is the ideal choice for tight-tolerance applications such as die and mold. The new Thermal Displacement Compensation System and Z-Axis cooling mechanism improves accuracy by tracking and compensating for machine temperature changes.

The all new HGM2 and NP2 circuit is standard and provides ultra-fine, satin surface finishing anywhere on the table surface. An enhanced Glossy Mirror Finishing Circuit “LLTX” improves mold releasability without the need for polishing.

These machines are the compact Highly-Rigid Machines and fixed Table Traveling Column Construction and with all-new Intelligent Digital Power Master (IDPM3) is the key to the special performance attributes of the ¬SV-P. The addition of the new SS Jump optimizes jump up acceleration control to stabilize high-speed burning.

The heart of the SV-P series is the GV80P generator for maximum performance with minimum wear with graphite electrodes is required in mould making, whether carbide must be economically machined, or even unusual tasks such as the machining of titanium or PCD, the GV generator is ideally equipped for all tasks.

High rigidity construction is realized by structural change of cast and Middle-Large area machining performance is improved (machining time, electrode wear).

With the all new functions to further innovate machining performance.

| Standard Machine Specifications | ||

|---|---|---|

| Machine travel [ X x Y x Z ] (mm) | - | 400 x 300 x 300 |

| Max. work-piece dimensions [ W x D x H ] (mm) | - | 900 x 650 x 350 |

| Max. work-piece weight (Kg) | - | 1000 |

| Axis movement | - | Fixed table, Column Movement |

| Dist. b/w table & electrode mount face (mm) | - | 200 to 500 |

| Max. electrode weight (Kg) | - | 80 |

| Unit weight (Kg) | - | 3500 |

| Initial Dielectric fluid amount (Ltr) | - | 470 |

| Dielectric fluid chiller unit | - | In-build unit cooler |

| Method of Working tank door | - | Automatic elevation tank |

| Max. machining peak current (A) | - | 80 (120 option) |

| Power requirement (kVA) | - | 7 (10 option for 120 supply) |

| User memory capacity (GB) | - | 1 |

| Min. drive unit (µm) | - | 0.1 |

| C - Axis and Automatic tool changer | - | Available as option |

| Features related to Industry 4.0 | - | Remote 360 |