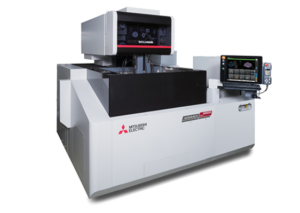

MV1200S

MV1200S Wire EDM machine is designed for Small and medium size part production and Medical Part Production with combination of High cutting speed, trend-precision and low consumption.

The machine exemplifies Mitsubishi EDM’s continued dedication to high precision and innovative technology with the highly reliable non-contact Cylindrical Drive System on the X & Y axis drives.

Less wire consumption, less power consumption, internal machine communication and power supply technology ensure economic benefits that pay off year after year.

With new features that will advance EDM machining, the MV1200S is truly a revolution in wire EDM technology.

Send Enquiry

Product Brochure

Promotion Video

Intelligent AT

Intelligent Submerged AT

Power Master

B-axis

Collision protection

On board CAM Feature

Product sales enquiry form

Customer Enquiry Form

Specification

| Standard Machine Specifications | ||

|---|---|---|

| Machine travel [ X x Y x Z ] (mm) | - | 400 x 300 x 220 |

| Machine travel [ U x V ] (mm) | - | ±60 x ±60 |

| Max. work-piece dimensions [ W x D x H ] (mm) | - | 810 x 700 x 215 |

| Max. work-piece weight (Kg) | - | 500 |

| Motor system [ axis ] (-) | - | XY axis LSM-OPT drive |

| Wire diameter range (Ø mm) | - | 0.1 to 0.3 |

| Max. taper angle (Degree) | - | 15⁰ @ 200mm, 30⁰ @ 87mm |

| Unit weight (Kg) | - | 2700 |

| Dielectric fluid tank capacity (Ltr) | - | 550 |

| Dielectric fluid chiller unit | - | In-build unit cooler |

| Max. output current (A) | - | 50.0 |

| Power requirement (kVA) | - | 13.5 |

| User memory capacity (GB) | - | 1 |

| On board CAD/CAM | - | Available, 2D CAM MAGIC |

| Min. axis resolution (µm) | - | 0.05 |

| Wire threading method | - | Automatic Wire Threading - Intelligent AT |

| Features related to Industry 4.0 | - | Remote 360 |