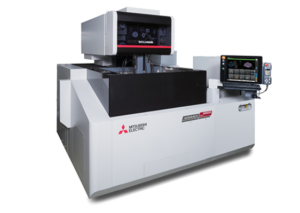

MV2400ST

MV2400ST Wire EDM is now capable of submerged cutting up to 420mm deep with the full support of the best auto threading system on the market today.

With an annealing length of over 530mm, this system is capable of threading the maximum work-piece height both at the start point and through the gap if needed for a break point insert.

With advancements in machine construction and power supply technology, the MV2400ST is sure to revolutionize EDM machining and increase your shop’s productivity.

Send Enquiry

Product Brochure

Promotion Video

Intelligent AT

Intelligent Submerged AT

Power Master

B-axis

Collision protection

On board CAM Feature

Product sales enquiry form

Customer Enquiry Form

Specification

| Standard Machine Specifications | ||

|---|---|---|

| Machine travel [ X x Y x Z ] (mm) | - | 600 x 400 x 425 |

| Machine travel [ U x V ] (mm) | - | ±75 x ±75 |

| Max. work-piece dimensions [ W x D x H ] (mm) | - | 1050 x 820 x 420 |

| Max. work-piece weight (Kg) | - | 1500 |

| Motor system [ axis ] (-) | - | XY axis LSM-OPT drive |

| Wire diameter range (Ø mm) | - | 0.1 to 0.3 |

| Max. taper angle (Degree) | - | 15⁰ @ 260mm, 30⁰ @ 110mm |

| Unit weight (Kg) | - | 3650 |

| Dielectric fluid tank capacity (Ltr) | - | 980 |

| Dielectric fluid chiller unit | - | In-build unit cooler |

| Max. output current (A) | - | 50.0 |

| Power requirement (kVA) | - | 13.5 |

| User memory capacity (GB) | - | 1 |

| On board CAD/CAM | - | Available, 2D CAM MAGIC |

| Min. axis resolution (µm) | - | 0.05 |

| Wire threading method | - | Automatic Wire Threading - Intelligent AT |

| Features related to Industry 4.0 | - | Remote 360 |